Selecting suitable test sieves with the correct openings ensures accurate particle sizing and characterization of soils, aggregates, grains, powders, and other materials while following ASTM and AASHTO standard test methods.

ASTM and ISO specifications establish requirements for wire diameter, aperture (opening) size, and other features of test sieves:

In addition to these standards describing test sieves, there are many published test methods from ASTM and other industry-related organizations that specify procedures for particle size sieve analysis of particular materials. A few examples are:

Other industries have unique test sieving methods that apply to foods, paints, and other granular materials.

Gilson test sieves are available with brass or stainless-steel frames fitted with brass or stainless steel woven-wire cloth meeting ASTM or ISO standards. Brass sieve cloth is limited to opening sizes from 2.36mm to 45µm (No. 8 to No. 325) for mounting in 8in or 12in (203mm or 305mm) brass frames. Although all stainless-steel sieves are more durable and often less expensive, all-brass sieves are still useful in some applications, such as those requiring non-sparking equipment.

Gilson carries popular frame diameters of 3in (76mm), 8in (203mm), and 12in (305mm), and many mesh sizes in ISO 200 mm and 300 mm frames in stock for immediate shipment. Other frame sizes, including 6in (152mm), 10in (254mm), and 18in (457mm), can be ordered. Unmounted ASTM Wire Cloth is also in stock. The sheet material is cut-to-order and meets ASTM E11 standards for opening sizes and wire diameters.

Test sieves are constructed with full-height or half-height frames. Full-height frames offer more space for agitation of larger particles, and half-height frames allow more sieves to be used in the same stack height when using a sieve shaker. 12in (305mm) diameter sieves also feature an option for intermediate-height frames.

You may need to factor in many different criteria to select the proper test sieves for your application. Our What Is A Sieve? blog post and this video will help you understand test sieves and the choices available to you.

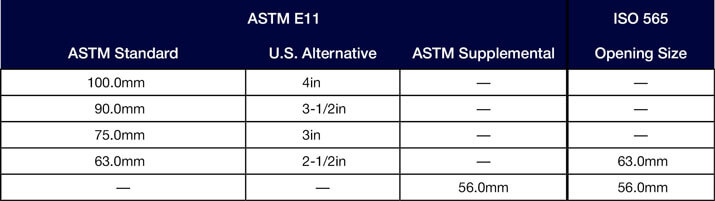

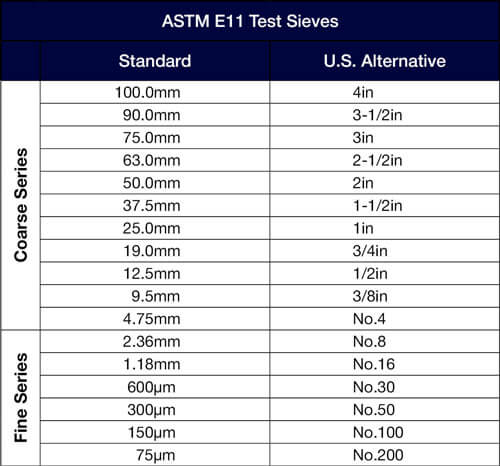

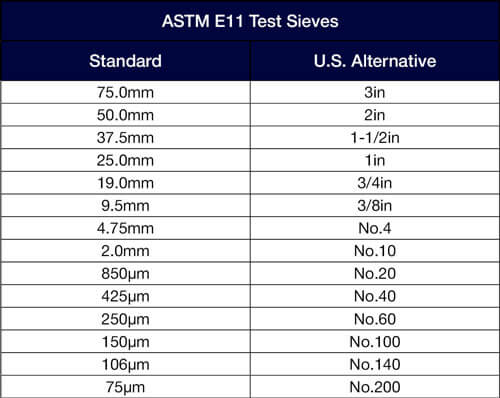

This table lists nominal ASTM sieve sizes in standard millimeter (mm) or micrometer (µm) units, along with equivalent U.S. alternative sizes by inch and mesh number (No.) designation. ASTM E11 now designates supplemental metric sizes that fill in the gaps between ASTM and ISO sizes. Corresponding ISO sizes in mm/µm are included.

Sieve Size Conversion Chart" width="715" height="201" />

Sieve Size Conversion Chart" width="715" height="201" />

Sieve opening sizes were initially defined in ASTM standards using imperial (inch) units of measure for apertures 1/4in (6.3mm) or above. Mesh number sizes for finer sieve cloth were determined by counting the number of apertures per linear inch. So, a No. 4 Sieve would have four openings in every linear inch. ISO openings are described in millimeters (mm) or micrometers (µm).

As a result of efforts toward harmonizing the standards, ASTM and ISO sieve specifications and tolerances are now very similar and, in many cases, identical. Both standards include specific requirements for aperture dimensions, mesh size, and statistical variations. For example, an ASTM 3/8in test sieve and an ISO 9.5mm sieve have identical opening sizes, wire diameter, and measurement tolerances and can be used interchangeably. Although popular ASTM 8in and 12in (203mm and 305mm) diameter sieve frames will not nest with ISO 200mm and 300mm frames, most sieve cloth sizes are available mounted in either size frame.

Also contained within ASTM E11 is a range of additional opening sizes classified as “supplementary sizes.” These 40 supplemental sizes fill in some gaps in the traditional ASTM lineup and are offered by Gilson mounted in 3in, 8in, and 12in (76mm, 203mm, and 305mm) stainless steel frames.

Different industries often specify a certain sieve size or set of sieve sizes to define particular material types. Particle sizing determinations are not limited to these sieve sizes, but they provide boundaries to classify the materials. The two examples shown below are for mineral aggregates used for the production of asphalt and concrete mixes, and for soils used in geotechnical engineering applications.

Conventional ASTM or ISO sieves are constructed using woven wire mesh that has been measured and inspected in the bulk form before being mounted in the sieves. These accurate and reliable sieves are standard, off-the-shelf test sieves intended for everyday use. They are classified as Compliance sieves and supplied with certificates of manufacturing compliance.

For applications where a higher level of accuracy, documentation, or traceability of sieving equipment is required, sieve verification services measure intact test sieves on NIST traceable instruments. They can provide two different levels of documentation that opening sizes and wire diameters meet or exceed ASTM/ISO specifications:

Sieves are subjected to hard use, whether in a sieve shaker or with manual sieve techniques. Sample loads cause distortion of the woven-wire mesh and abrasion results in a reduction of wire diameters, enlarging the openings beyond acceptable limits. Other options for ongoing validation of sieve accuracy and conformity are also available:

Sieve pans and covers collect fine material passing the sieves and prevent sample loss during handling and testing.

Backing cloth reinforces finer mesh sizes to stop sagging, tearing, and distortion of the mesh openings from repeated use. This factory-installed No. 30 (600µm) stainless steel backing preserves sieve accuracy and extends service life. Backing cloth can be ordered at the time of purchase for 8in or 12in (203mm or 305mm) diameter sieves with mesh sizes finer than No. 70 (600µm). The backing is positioned under the primary mesh, so verification of Inspection or Calibration grades is not possible after the backing is installed.

The Test Sieving Methods Sieve Analysis Procedures and Guidelines ASTM Reference Book, also known as Manual 32, offers well-researched guidelines for establishing sieve analysis procedures. The most recent 5th edition from committee E29 has updated information for sieves, sieving equipment, and procedures that correlate with ASTM standards across many industries. Revised tables, charts, and specifications are included.

Words and terms used in sieving can be confusing. Some sieving terms are unique to the industry, and others are used synonymously, e.g., aperture size and mesh opening, or micron and micrometer. A complete listing of sieving terminology is found in ASTM E1638.

(1) a surface provided with apertures of uniform size and shape;

(2) another term used interchangeably for woven wire cloth;

(3) a machine provided with one or more screen surfaces

Below you will find a useful ASTM Standard and Alternate, and ISO Sieve Sizes chart. For a PDF copy, print, or download a copy of this sieve size conversion chart, click here.

| ASTM E11 | ISO 565/3310-1 | |

|---|---|---|

| Standard | Alternate | Size |

| 100 .0 mm | 4in | - |

| 90.0mm | 3 1/2in | - |

| 75.0mm | 3in | - |

| 63.0mm | 2 1/2in | 63.0mm |

| - | - | 56.0mm |

| 53.0mm | 2.12in | 53.0mm |

| 50.0mm | 2in | 50.0mm |

| 45.0mm | 1 3/4in | 45.0mm |

| - | - | 40.0mm |

| 37.5mm | 1 1/2in | 37.5mm |

| - | - | 35.5mm |

| 31.5mm | 1 1/4in | 31.5mm |

| - | - | 28.0mm |

| 26.5mm | 1.06in | 26.5mm |

| 25.0mm | 1in | 25.0mm |

| 22.4mm | 7/8in | 22.4mm |

| - | - | 20.0mm |

| 19.0mm | 3/4in | 19.0mm |

| 18.0mm | - | 18.0mm |

| 16.0mm | 5/8in | 16.0mm |

| - | - | 14.0mm |

| 13.2mm | 0.530in | 13.2mm |

| 12.5mm | 1/2in | 12.5mm |

| 11.2mm | 7/16in | 11.2mm |

| - | - | 10.0mm |

| 9.5mm | 3/8in | 9.5mm |

| - | - | 9.0mm |

| 8.0mm | 5/16in | 8.0mm |

| - | - | 7.1mm |

| 6.7mm | 0.265in | 6.7mm |

| 6.3mm | 1/4in | 6.3mm |

| 5.6mm | No. 3 1/2 | 5.6mm |

| - | - | 5.0mm |

| 4.75mm | No.4 | 4.75mm |

| - | - | 4.50mm |

| 4.00mm | No.5 | 4.00mm |

| 3.55mm | - | 3.55mm |

| 3.35mm | No.6 | 3.35mm |

| - | 1/8in* | - |

| 3.15mm | - | 3.15mm |

| 2.80mm | No.7 | 2.80mm |

| - | - | 2.50mm |

| 2.36mm | No.8 | 2.36mm |

| 2.00mm | No.10 | 2.00mm |

| - | - | 1.80mm |

| 1.70mm | No.12 | 1.70mm |

| - | - | 1.60mm |

| 1.40mm | No.14 | 1.40mm |

| - | - | 1.25mm |

| 1.18mm | No.16 | 1.18mm |

| - | - | 1.12mm |

| 1.00mm | No.18 | 1.00mm |

| - | - | 900µm |

| 850μm | No.20 | 850µm |

| - | - | 800µm |

| 710μm | No.25 | 710µm |

| - | - | 630µm |

| 600μm | No.30 | 600µm |

| - | - | 560µm |

| 500μm | No.35 | 500µm |

| - | - | 450µm |

| 425μm | No.40 | 425µm |

| - | - | 400µm |

| 355μm | No.45 | 355µm |

| - | - | 315µm |

| 300μm | No.50 | 300µm |

| - | - | 280µm |

| 250μm | No.60 | 250µm |

| - | - | 224µm |

| 212μm | No.70 | 212µm |

| - | - | 200µm |

| 180μm | No.80 | 180µm |

| - | - | 160µm |

| 150μm | No.100 | 150µm |

| - | - | 140µm |

| 125μm | No.120 | 125µm |

| - | - | 112µm |

| 106μm | No.140 | 106µm |

| - | - | 100µm |

| 90μm | No.170 | 90µm |

| - | - | 80µm |

| 75μm | No.200 | 75µm |

| - | - | 71µm |

| 63μm | No.230 | 63µm |

| - | - | 56µm |

| 53μm | No.270 | 53µm |

| - | - | 50µm |

| 45μm | No.325 | 45µm |

| - | - | 40µm |

| 38μm | No.400 | 38µm |

| - | - | 36µm |

| 32µm | No.450 | 32µm |

| 25µm | No.500 | 25µm |

| 20µm | No.635 | 20µm |

We hope this blog post has given you insight on test sieve opening sizes, please contact our testing experts for further assistance in selecting the right opening size for your testing applications.